Search For

Are you looking for a solution for cosmetic products, such as fragrance caps, compacts or lipgloss packaging? Or do you require a solution for pharmaceutical products, such as pill containers, a dosage cap or measuring spoons? Or perhaps you need a plastic packaging solution, with or without in-mould labelling, for your food products? You are welcome to contact us, to address all your specific product requirements in the field of safety, hygiene, materials and design. For several decades, we have been manufacturing all manner of technical products with applications in the various markets.

STAGE 1

Testing and development

Presentation, assessment and testing of your solution can be carried out on the basis of a 3D drawing, and prototypes and/or products by means of 3D printing or using a low-cost test mould. Once the product concept has been approved, we proceed to design the right mould in-house. Based on your purchase forecasts, we select either a single, multiple, stack or two-component mould.

Any colour with extrusion

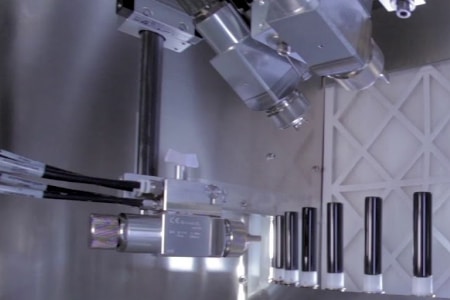

After the design has been approved and the moulds developed, we put your product into production. We do so using various techniques, materials and fully automated processes. We also have several two-component injection moulding machines at our disposal.

STAGE 2

Manufacturing and finishing

Our high-tech machinery enables us to produce practically any plastic packaging

in any volume required. We apply the appropriate techniques to make your product unique.

In-Mould Labelling (IML)

IML is a technique in which we fuse a plastic label with images and/or text with a product during injection moulding. In-mould labels have excellent resistance to moisture and temperature changes. Furthermore, the labels are scratch, tear and wrinkle resistant and fully recyclable. Because IML is performed simultaneously with injection moulding, and no further finishing is therefore required, optimum product hygiene is guaranteed.

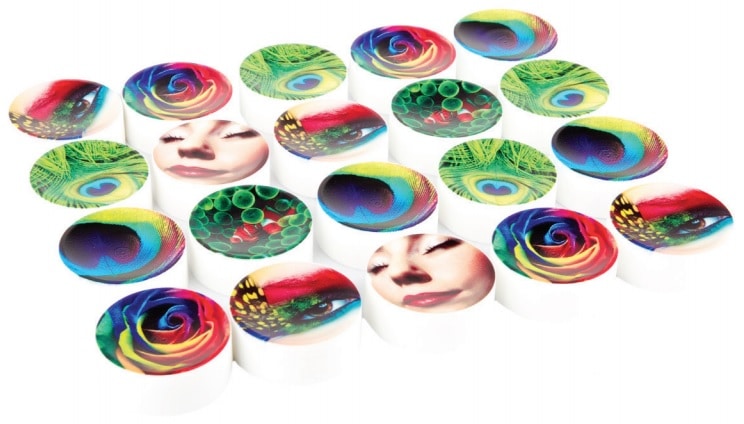

Digital printing

This new technology will enable us to print your flat and convex products at high speed. We will then have the capacity to carry out in-house printing ranging from a single colour to full colour, including UV protection. This technology is highly suitable for printing plastic lids and caps, but also for the flat sides of a cap or plastic bottle.

Hot stamping

Hot stamping allows us to use foil to apply a logo or text, for example, to personalise your product or to give it a more distinctive appearance. Hot stamping is suitable for both straight and curved surfaces.

Metallization

Metallizing your product lends it an exclusive look. The application of a high vacuum vapour deposition technique enables us, for example, to gold or silver plate your product.

Pad printing

We can carry out pad printing of your product on any surface and in any form. In fact, you can event opt to have us print your products in various colours.

Painting

After injection moulding, we also offer the option of painting your product in any colour required. We have two automated paint shops of our own, and can also rely on the services of partners.

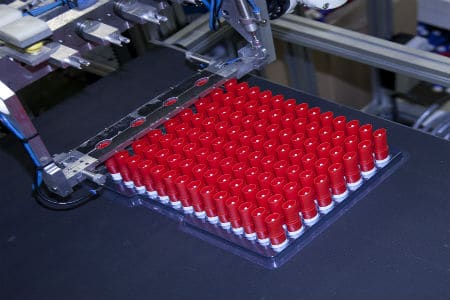

STAGE 3

Assembly and distribution

Aarts Packaging 10,000m² site also comprises our own warehouse and distribution department. We carry out the in-house assembly of products. And last but not least, we package and ship the products in the manner and quantities you require.